ABB’s MPS Production Integrates Printing With Other Processes Including Plate-Making & Newsprint Handling

Success for publishers and printing houses can only be achieved with suitable systems for the automation of the various processes. MPS Production from ABB provides unparalleled functionality for managing printing presses and optimizing the print process itself. Furthermore, it has an extensive range of interfaces for integrating the print process with other processes like plate-making and newsprint handling.

Standard interfaces of MPS Production mean that the system can be used not only with presses with ABB controls but also with press control systems from various other suppliers. Its functionality begins with the planning of the print product itself. The product specification can either be imported from an external system or created using MPS Production’s graphical product planner. MPS Production includes a virtual representation of the printing presses as installed at the relevant site. This means that the system is not only able to establish which products can be produced on these presses, but also what options are available for the print jobs themselves, what paper leads can be used and how the print jobs can be optimized.

Standard interfaces of MPS Production mean that the system can be used not only with presses with ABB controls but also with press control systems from various other suppliers. Its functionality begins with the planning of the print product itself. The product specification can either be imported from an external system or created using MPS Production’s graphical product planner. MPS Production includes a virtual representation of the printing presses as installed at the relevant site. This means that the system is not only able to establish which products can be produced on these presses, but also what options are available for the print jobs themselves, what paper leads can be used and how the print jobs can be optimized.

![]() Greatest Benefits

Greatest Benefits

The greatest benefits of MPS Production for print quality are realised in the area of presetting the press. The combination of proven paper-lead or imposition-specific values for registers/compensators and web tension, that have been read back from the press, together with ink and water presetting with detailed calibration and speed dependent curves means that MPS Production brings major reductions in make-ready time and start-up waste. The benefits go on much longer.

Highly User Friendly

MPS Production has a highly graphical, user-friendly interface that PC users will rapidly feel at home with. The screen is generally divided into four sections. At the upper left is the tree structure for the selection publication, print product, print job or whatever is relevant. The central area is used for inputting of parameters. On the upper right is a graphical representation which, depending on the current function, will show relevant information such as the product structure or the selected imposition. The lower part of the screen is generally used to show the scheduling with the print jobs that can be shifted both in time and from press to press by drag & drop.

Functions And Benefits

Product planning: Although MPS Production can import product specifications from editorial systems, it also has full product planning functionality. The system is therefore suitable for all sizes of printing plants, with or without integration. Both editorial and third-party products can be defined in the one system. Broadsheet, tabloid and mixed products are all supported.

Product planning: Although MPS Production can import product specifications from editorial systems, it also has full product planning functionality. The system is therefore suitable for all sizes of printing plants, with or without integration. Both editorial and third-party products can be defined in the one system. Broadsheet, tabloid and mixed products are all supported.

Production planning: Once a product has been defined, its production can be planned. Relevant production parameters are set in the attribute part of the user interface. This includes selection of the production variant to be used for the print job. If the user wishes, the system will select the production variants for a production sequence automatically to ensure that as many web leads as possible are reused. This reduces the make-ready time between print jobs.

Production planning: Once a product has been defined, its production can be planned. Relevant production parameters are set in the attribute part of the user interface. This includes selection of the production variant to be used for the print job. If the user wishes, the system will select the production variants for a production sequence automatically to ensure that as many web leads as possible are reused. This reduces the make-ready time between print jobs.

Plate management: MPS Production knows exactly how many plates are required and where on the press they belong. This data is shared with plate management systems, thereby allowing a complete automation of the plate making. In addition, the relevant data can be supplied to optional plate displays mounted on the press itself. Forced panorama production is fully supported.

Automatic imposition generator: If no predefined imposition is available or if those defined do not meet the requirements of the user, then new production variants that correspond to the current product can be generated at the touch of a button. The number of impositions generated can be restricted by selecting individual reel stands or by specifying certain web widths.

Graphical imposition editor: The graphic imposition editor makes it much easier to create and modify basic impositions. The user can select webs, ribbons and bundles for the basic imposition via a graphic user interface and define the relevant web widths and turns. Therefore profound knowledge of naming conventions and paper lead drawings is no longer required.

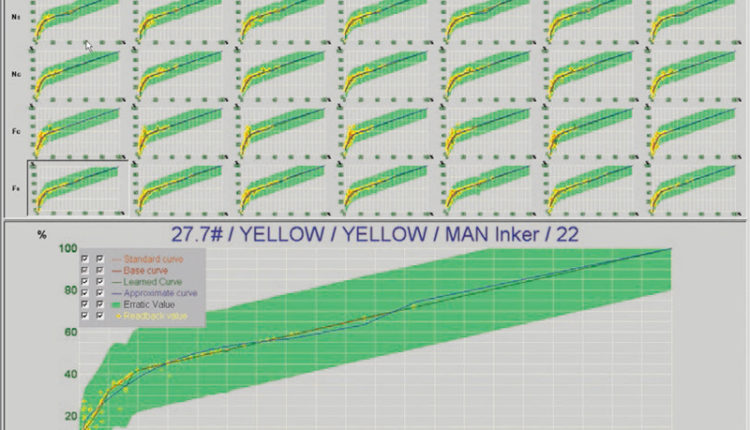

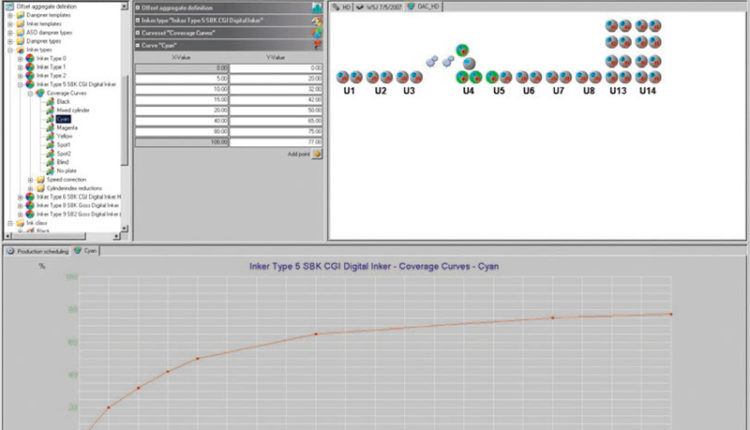

Ink, water and paper management: This is where MPS Production has a profound effect on the print quality. The system caters for all available inking and dampening systems. With 16 classes of ink for each of up to 10 different inker types, the system offers unrivalled flexibility and precision for ink presetting. It is therefore possible to assign different inker curves to different printing couples.

Automated inker curves: This option has been introduced for the benefit of those users who would like to have the possibility for an automatic updating of the ink curves based on the values used by the printers. An important aspect is that the user decides whether the curves should be updated and whether the updated curves should be used. The user therefore does not lose control over this important aspect of print quality.

Presetting: Short set-up times and minimised start-up waste are ensured by the wide selection of preset functions for all circumstances. The preset uses compensator and web tension values from previous print jobs using either the same production variant, imposition, web-ribbon-bundle combination or individual webs, ribbons and bundles, depending on what is available.

Presetting: Short set-up times and minimised start-up waste are ensured by the wide selection of preset functions for all circumstances. The preset uses compensator and web tension values from previous print jobs using either the same production variant, imposition, web-ribbon-bundle combination or individual webs, ribbons and bundles, depending on what is available.

Version management: MPS Production’s detailed print product and page content version management enables a precise control of the presetting. The user can always see which version is currently on the press and where there are newer versions available. This is essential when using highly integrated presses with image-based controls, automatic plate loaders and soft-proof systems.

Overviews of ready and active print jobs: MPS Production provides an overview of all ready and active print jobs. The scope of the list of ready jobs can be reduced by the use of filters. Many of the fields in the displays can be edited, for example, circulation values and timings.

Equalizer: Equalizer means that print jobs running in parallel on several presses are balanced such that all jobs finish simultaneously on reaching the required total print run. If one press is stopped, either manually or by a disturbance, then the remaining print run for this press is redistributed amongst the remaining presses.

Production monitoring and forecasting: As per schedule MPS Production shows the actual production times for running and completed jobs. These are shown as a separate bar along the time axis. Delays can therefore be identified immediately. In the event of a production delay a forecast is prepared for the subsequent print jobs. This is also shown graphically on the schedule.

Print quality data collection: This is a logging function that creates a chronological record of all the values used in the course of a print job. The data are stored in a database for subsequent analysis and the generation of reports.

Operator intervention log: This optional function records not only the preset values of all adjustable elements on the press but also all changes made by the operators at the press control console. The recorded values are then consolidated at the end of the print job into a report which shows the initial (i.e. preset) value, the final value, the minimum and maximum values and the number of changes made to each of the controlled elements.

Online Production Viewer: The Online Production Viewer module of MPS Production provides a production overview on smartphones, tablets or PCs, so the production director can see what is going on in his plant wherever he or she is.

Print job queue display: The print job queue display is configurable. It typically shows the previous two print jobs on a press section, the running print job and the next planned job. The data includes product name and structure, schedule info (on time, delayed etc.), circulation and so on.

Active print job display: The active print job display shows the graph of the press speed over the job, the planned and actual production times and a lot of other key data. There is also a more detailed view with all stop messages and alarms.

Active print job display: The active print job display shows the graph of the press speed over the job, the planned and actual production times and a lot of other key data. There is also a more detailed view with all stop messages and alarms.

Press progress display: The press progress display gives a graphical overview of the progress of the current print jobs on all press sections.

Report function: Finally, there is the report function which shows reports that are also available on the main MPS Production system, i.e. the production manager gets a preview of the reports and data that he or she will see when back in the office.

Flexibility For Today And Tomorrow

ABB recommends system virtualization. Previously virtualization was made prohibitively expensive by the Oracle license model, but MPS Production is now based on the PostgreSQL database, which provides all the functionality required by MPS Production without the punitive license costs. Virtualization

means that the application can be moved to a new platform very simply, thereby freeing users from the challenges imposed by the hardware and operating system life cycles. Virtualization allows an additional copy of the application to be deployed in parallel with the original version.

A New Evolution

ABB has a policy of ensuring upwards compatibility of its products, and MPS Production is a classic example of this. The first predecessor of MPS Production was introduced as far back as 1977, when it was the world’s first computer system for newspaper production planning and press presetting. The system has subsequently gone through many phases of evolution, keeping up with the development of new hardware, operating systems, programming languages, and, of course, the changing needs of the industry. ABB has supplied several hundred systems in this long history.

Greatest Benefits

Greatest Benefits