|

Main Stories

Advert

Innovative roller coverings for film dampening rollers

A new awareness and legislative situation with regard to health and safety and environmental issues, along with significant and increasingly incalculable variations in the price of IPA have in recent years encouraged press operators to reduce or even eliminate the use of IPA in offset printing. Higher press speeds, reduced levels of IPA and – last but not least – new developments in the chemistry of offset inks bring new and very particular demands on both fountain solution additives and dampening rollers in modern offset presses. When selecting the ideal fount additive and roller materials for a given application, consideration has to be given to the specific demands of each press configuration and the inks used. Finally, the quality and economic expectations of the customers and the operating conditions of the individual printing company have to be taken into account. Böttcher has developed a broad range of dampening roller compounds to cater for all these parameters, as in today’s complex global environment, the key to success is not one single concept, but the intelligent combination of the many different options to suit the individual customer’s situation. The influence of dampening rollers in offset printing Each roller position in the dampening train has a very specific and unique role to play in the printing process. Particularly in modern presses and with reduced or no use of IPA, this calls for customised covering materials for each roller position. Demands on dampening rollers

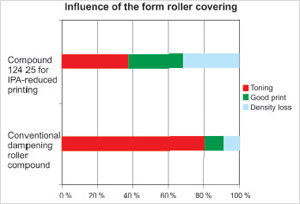

When the film is transferred to the form dampener, the fount film is stretched, since the form roller rotates at a significantly higher speed than the hard pan or metering roller. It is important that a certain amount of water is integrated into the ink, as it is largely this integrated water which ensures that fine negative lines in the printed images are kept open as this water is released again when the film is applied to the printing plate. Specialised form roller compounds actively support this process.

Form dampening rollers are in continual contact with ink and ink-water emulsions, and must therefore be chemically resistant to the inks in use. An inking roller compound would obviously also afford this resistance, but would provide inadequate dampening performance. Böttcher has been supplying the 124 25 compound for alcohol-reduced or alcohol-free printing in conjunction with conventional offset inks for many years and with great success. For UV and dual purpose printing, the new compound 134 25 has been added to the Chameleon series of compounds. This compound offers both excellent dampening properties and extremely high dimensional stability in both UV and conventional inks. Demands on pan and metering rollers The primary job of pan and metering rollers is to provide a consistent dampening film. The hard pan or metering rollers have to accept the water film in the nip and subsequently transfer it evenly to the form dampening roller. Inconsistencies in this film have an immediate negative effect on the printed image. Negative physical phenomenae during film splitting Dynamic disturbances in the flow of the liquid in the transfer nip can lead to printing problems. For example, the phenomena of cording, which can arise in the separation phase of the nip between the pan and the metering roller, can be carried forward to the printing plate and be visible as fine lines in the printed image. Stripes of this nature are a result of dynamic film-splitting processes, their occurrence depends on a number of factors, such as the rotational speed of the dampening rollers, roller settings, temperature, the viscosity and surface tension of the fountain solution and many other parameters. Even small variations in any of these parameters can give rise to or prevent the occurence of these stripes. With regard to the pan roller, the problem can be approached from different angles, depending on the specific situation on a given printing press. For many printers with mid- or large-format presses – particularly in packaging applications – the problem could be solved by the use of pan rollers with a rougher, but clearly defined surface structure, which significantly increased the ability of the roller to mechanically pick up and carry a higher volume of water. This in turn allows the operator to reduce the speed of the roller in the dampening train, thereby removing the potential for cord stripes to arise. In other cases, the use of a different rubber compound which retains a higher degree of elasticity at low temperatures provides a positive influence on the film splitting process and eliminated the appearance of cording. The new ProAqualis generation of pan roller coverings with its special surface technology gives the printer unparalleled performance in splitting and transferring an even film of dampening solution. Negative chemical reactions and side-effects

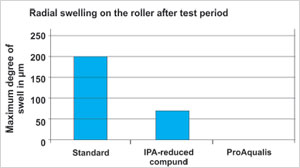

Depending on the type of ink, the covering material on the pan roller and the fount additive in use, this feedback can quickly lead to localised radial swell of the pan roller covering and to a variety of print problems. So far, it has not been possible to fully identify all factors contributing to this problem, but it has been possible to replicate the problem in a specially adapted dampening unit simulator. This in turn enables the researcher to identify the scale of the potential problem when using different roller covering materials, while at the same time investigating the influence of different fount additives and other materials and parameters in the occurrence of the problem. Based on the results of this research, the classic dampening roller compounds have been further developed and refined, leading to the introduction of the compound 147 25 as the standard compound for both dampening pan and metering rollers with the highest level of protection against radial swelling. However, in practice, there still remain some combinations of ink and fount additive which – in extreme circumstances – can cause a degree of residual radial swelling, even on this compound. The solution: the new pan roller compound ProAqualis The use of a composite roller covering represents a new, innovative alternative to homogenous rubber coverings. Such a composite solution is the ProAqualis covering, which consists of a customised dampening roller base compound to which an additional functional coating is applied. This coating is made of a highly specialised elastomer material, which is chemically extremely resistant to the components of both inks and fount additives and protects the base rubber layer from attack by these materials. The coating process results in a matt surface of defined roughness, combining excellent water transfer capability with ink-repellent properties and virtually complete insusceptibility to swelling. The highly dynamic base rubber guarantees the necessary elasticity and adaptability in the roller nip for optimum performance at all press speeds. A specific advantage of the ProAqualis system is its high degree of compatibility with roller washes and the polar solvents typically contained in many dampening and metering rollers cleaners and UV washes available in the marketplace. The ProAqualis rollers have been successfully tried and tested in a large number of both sheet-fed and web presses, typically running at IPA levels of between zero and eight percent. ProAqualis has also become the standard pan roller covering on new presses for several of the leading press manufacturers. Fig. 3 shows the results of a test series in which 3 different dampening roller compounds were exposed for a defined period of time to swell-inducing materials. After exposure, the degree of swell was determined by measuring the rollers on a laser measuring device (Fig. 4). nnn

|