|

Main Stories

David Preskett becomes Ipex 2014 president

Ipex highlights potential for expanded Goss and SEC product portfolio

More than twenty years after its initial move into the print sector, the subsidiary printing and packaging machinery companies of SEC today produce press, finishing and auxiliary components for the worldwide market. Current brands and products associated with SEC encompass a broad range of applications. Under brand names such as Akiyama, Purlux, Guanghua, Yawa, Shen Wei Da and Feida, product lines for sheetfed printing, binding, diestamping, foiling and guillotining are designed to deliver world-class performance and high value. Goss International supplies web offset presses and finishing systems for newspaper, magazine, catalogue, direct mail, packaging and other printing applications. According to SEC chairman Xu Jianguo, “Full ownership of Goss International enhances our presence in the print sector, our world-class product portfolio and our ability to deliver innovation, value and security to a wider range of printers and publishers.” It will create opportunities for Goss International and Shanghai Electric (Group) Corporation companies to pursue joint product development initiatives, integrate and enhance sales and support capabilities in some regions, and optimize manufacturing operations throughout America, Asia and Europe. “Being market leader in web offset sectors with global manufacturing, sales and support network, Goss is a key addition to Shanghai Electric print strategy. Goss and SEG share an international outlook and a focus on working with customers to realize innovative, technology-driven solutions,” said Jochen Meissner, president and CEO, Goss International. MGE’s PressMate systems demonstrated A selection of MGE’s PressMate systems was seen in action at Ipex 2010 running on the new Komori Enthrone 529 press. The press was fitted with a PressMate CS530 dampening circulator, PressMate MX3 Additive Doser, and the PressMate FX-1 Fount-Xtend filtration system. In addition, PressMate RO – 1400 Reverse Osmosis water purification unit was also in use on the Komori stand ensuring the availability of a clean, pure water supply to their equipment. “We are extremely happy that Komori have chosen to run several units from our PressMate range of ancillary press equipment as part of the worldwide launch of one of their presses,” said Graham Martin, managing director, MGE UK, adding, “Our PressMate units are well proven in the market and it is fantastic that Komori have the confidence and trust in MGE’s product to select them to be run at such an important event for their company.” (www.mgeindia.com) Tolerans promotes innovative stitching solutions At Ipex 2010, one of the world leaders in innovative stitching solutions, Tolerans exhibited as part of the PrintCity Alliance stand in hall 17. With the outstanding success of their Speedliner series of stitchers, Tolerans has now come to the next level, creating Speedliner 2.0, a high-end stitching system that is even easier to maintain and operate, reducing cost of maintenance and minimizing down-time. Their slimmest model, Speedliner S60 Compact, is designed to fit in even the narrowest spaces in the press, perfect for printing plants that haven’t had enough space for a stitcher before. Stitching, or stapling, newspapers and commercial print is a growing trend all over the world, mainly because it’s highly appreciated by readers and advertisers. And for printers, it doesn’t just add value to the product, it’s a cost-effective way for a printing operation to broaden its market and increase revenue. “By stitching in-line, at full production speed, printers can reach significant cost savings on the total production cost. In-line stitching offers one seamless way to move part of the finishing process right into the press,” said Jan Melin, CEO at Tolerans. And in this changing media landscape, printers need to look for new business opportunities and maximize the use of their press. By offering stitching, they can use any spare capacity to print inserts, advertising supplements, brochures and magazines, at full production speed. Stitching has in fact already become the norm in many places, and experts believe this paradigm shift is becoming the industry standard. New trade show concept well appreciated manroland came with overall solutions rather showcasing any equipment, providing adequate time for their offering to help enhance the customers’ understanding. On the manroland’s stand at Ipex in Birmingham, everything revolved around the needs of the printing industry: production flexibility, differentiation possibilities, reduced investment and operating costs, automation features and sustainable production. “We showed without any doubt that we are a high-performance and energetic company that, with groundbreaking technology and services expertise, sets the benchmark for customer orientation. We are very pleased to report new projects and orders from newspaper, advertising, packaging, and commercial printing segments,” summarized, Gerd Finkbeiner, CEO, manroland. “At last we have managed to turn the mood around to positive once again as opposed to the negative mood that has persisted almost since the last drupa. It is a great success for manroland that our customers really liked our new trade show approach,” added Thomas Hauser, marketing vice president.

Almost every day during Ipex, manroland offered additional technology forums in Offenbach. During these one-day events, customers and suppliers learned about the latest developments in theory and practice, as well as trends and innovations. Customers from fourteen countries attended the event combined with their travel to or from Ipex. Simple technology for low production costs At Ipex 2010, simple, modular solutions for low-cost production were placed at centre stage by Ferag and WRH Marketing. The technology showcased at Ipex 2010 involved a compact EasySert line for the 2-in-1 inserting process and the StreamFold quarterfold system in combination with the new JobTrim three-side trimmer and JobStack 90 compensating stacker. The key features of these solutions are: versatile utilization; needs-based configuration; simple expansion options; and – due to fast set-up times and stable running – low costs per copy. Each of these aspects plays its part in guaranteeing high profitability and investment security in modern commercial production. Besides, in an offline system for supplement and booklet production, Ferag and WRH Marketing showed how the StreamFold quarterfold unit can be put to flexible use in the commercial printing business. At the same time, the JobTrim three-side trimmer celebrated its world premier. EasySert integrated into UniDrum gatherer-stitcher line The Oberndorfer Druckerei GmbH in Oberndorf (Austria), one of Europe’s leading web offset printers, has opted for Ferag’s UniDrum technology. For the first time, EasySert inserting will be integrated into a gatherer-stitcher installation. The inserting system will be used for inline processing of up to two advertising supplements into the stitched and trimmed products. The opening sequence is possible either via overlap, or air in the case of trimmed products. Other Related News nnn

|

Ipex 2010 president George Clarke (right) congratulating new elected president David Preskett.

Ipex 2010 president George Clarke (right) congratulating new elected president David Preskett.

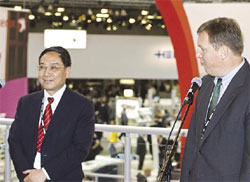

Xu Jianguo, chairman of SEC and Jochen Meissner, president and CEO of Goss International.

Xu Jianguo, chairman of SEC and Jochen Meissner, president and CEO of Goss International.

Gerd Finkbeiner (middle) explaining manroland’s strategy and technology to the international trade press at the Ipex press conference held in the VAP theater, the star attraction at Ipex 2010.

Gerd Finkbeiner (middle) explaining manroland’s strategy and technology to the international trade press at the Ipex press conference held in the VAP theater, the star attraction at Ipex 2010.